Design and Production of the Mark 18 Torpedo

Photo of Westinghouse Post Card, Pittsburgh, Pennsylvania.

Westinghouse, a well-known company in the Pittsburgh area, was involved with the development and manufacturing of electric-drive torpedoes during and after the Second World War.

Beginning in 1869, the design, testing, and manufacturing of torpedoes for the Navy took place at the Naval Torpedo Station (NTS) at Newport, Rhode Island. In 1919, the NTS started work on the development of an electric-drive torpedo, an evolution of the submarine torpedoes prior to and during World War I being steam-driven; a turbine was driven by a mixture of steam and alcohol. The biggest advantage of an electric-drive torpedo is the absence of a “wake” which could be seen by the target ship and aircraft. Whereas a steam-driven torpedo has a “wake” caused by the engine exhaust.

Aerial Photo, Naval Torpedo Station.

However, the electric-drive torpedo is not without its disadvantages. Examples of various disadvantages of an electric-drive torpedo include slower speed and shorter range due to the limitations of the battery power supply. Also, electric torpedoes must be withdrawn from torpedo tubes periodically to recharge the batteries.

The NTS work on the electric torpedo ceased in 1931 due to the suspension of funding during the Great Depression. Ten years later, in July 1941, the Bureau of Ordnance restarted the electric torpedo project at the NTS, partnering with General Electric and Exide Batteries. (Note: Exide Batteries originated in 1888 as the Electric Storage Battery Company in Philadelphia. One of its early projects was to manufacture the batteries for the Navy’s first submarine, the USS Hunley, in 1899.)

When war broke out in December 1941, torpedo manufacturing became urgent. During the Imperial Japanese attack on the Cavite Naval Yard in the Philippines shortly after the attack on Pearl Harbor, 233 torpedoes were lost to the Japanese Navy. NTS focus on manufacturing and the electric-drive project moved slowly.

Worth noting - in January 1942, Britain gave a captured German electric torpedo to the U.S, Navy for deconstruction and review of the technology. This was later accompanied by a captured German submarine, U-570, that had a full load of these G7e torpedoes, which were performing well for the German Navy. Later, several more of these German torpedoes were found on U.S. east coast beaches.

Photo of Westinghouse Mark 18.

Chief of Naval Operations Ernest King ordered an acceleration of the electric torpedo work. However, both General Electric and the NTS were already overwhelmed with work. Thus, the Navy approached Westinghouse to see if it would take on the project. Westinghouse suggested that copying the German G7e torpedo would be the quickest route to a prototype for testing. Westinghouse delivered its five prototypes to Newport within fifteen weeks, using its facility in Sharon, PA to complete the prototype work, with Exide in Philadelphia providing the batteries.

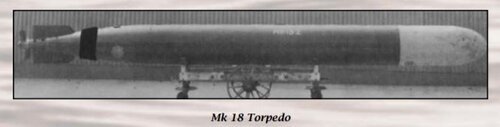

Photo of Mark 18 Torpedo.

The new electric torpedo was designated the Mark 18 but testing did not begin at Newport until November 1942. Since the electric torpedoes did not leave a wake, the NTS had to develop a system of lights to allow tracking the Mark 18 during night-time testing. Subsequent testing revealed issues requiring modification of the prototype design. For example, the German G7e was designed for German torpedo tubes and associated firing system - clearly a respective difference with the Mark 18 requiring adaptation to U.S. submarines.

Aerial Image of the Sharon, PA facility.

The Sharon, PA plant produced its first Mark 18 production torpedoes in April 1943. Unfortunately, due to shipping, training, and testing delays in the fleet, the first deployment of Mark 18 torpedoes in the Pacific theatre occurred in September 1943. During the first few months of use a few easily fixed problems were discovered. Once addressed, the torpedo performed accordingly.

The Mark 18 was 20 ½ feet long, weighed 3,000 pounds, carried a 600-pound explosive charge, traveled at 29 knots, and had a range of 4,000 yards. Westinghouse produced thousands of Mark 18 torpedoes during and after the war. In 1945, the Mark 18 accounted for 65% of submarine torpedoes fired in the Pacific theatre.

Westinghouse was also involved with the development of Cold War torpedoes, including the Mark 37 and the Mark 48.

Sources:

Blair, Clay. (1975). Silent Victory: The U.S. Submarine War against Japan. Naval Institute Press. ISBN 1-55750-217-X.

Milford, Frederick. (January 1997). US Navy Torpedoes, Part 3: WWII development of conventional torpedoes 1940-1946. The Submarine Review, pages 67-80.

Wildenberg, Thomas; Polmar, Norman (2010), Ship Killer: A History of the American Torpedo, Naval Institute Press. ISBN 978-1-59114-688-9.